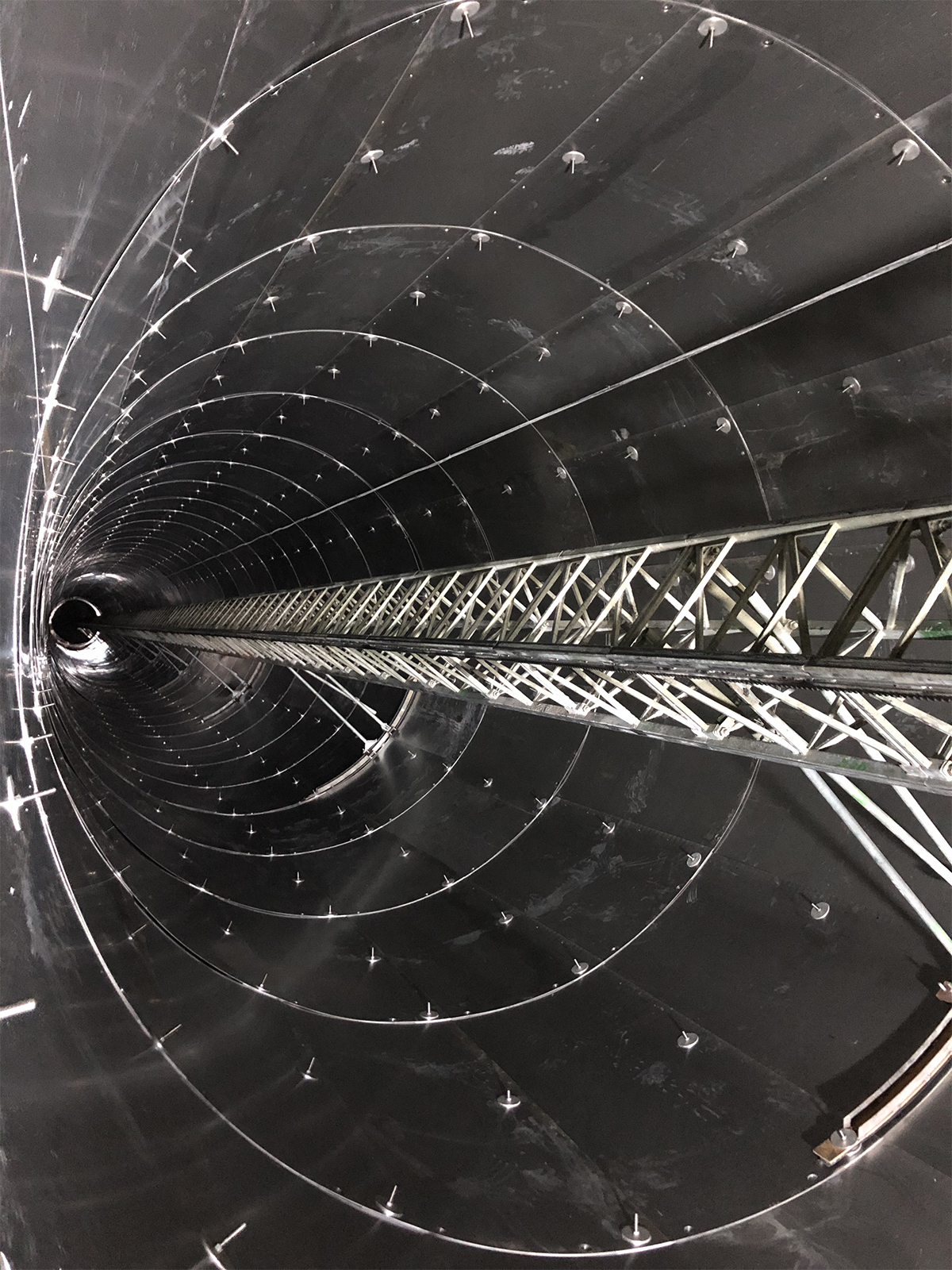

”The whole thing was challenging. By then, we had already done a similar work in the staff shaft, so we already knew a little about how to start strengthening the capsule shaft,” Säippä describes.

According to Säipä it went well to work with JIITEE Työt. At the beginning of the project, the employees of JIITEE Työt were introduced to the safety culture and operating methods of the construction site, after which the work could be started according to plan.

According to Säippä, the work was fluent throughoutthe project:

”We have close supervision on the construction site, because that’s what the excavation conditions require. The collaboration with JIITEE Työt worked really well, everything went smoothly, and the team was good. They took care of occupational safety and did what they promised during the time we had agreed.”

JIITEE Työt has also carried out other project work for Posiva after the reinforcement of the capsuleshaft, and according to Säippä a new project at the construction site is about to start again.

”Strengthening the capsule shaft was a really challenging project right from the design stage. JIITEE Työt had no previous experience with this reinforcement method, but the uniqueproject was still successful, Säippä sums up.